Download Tripod Beta Software Company

» Tripod Beta: Guidance on using Tripod Beta in the investigation and analysis of incidents, accidents and business losses is the current manual on using the Tripod Beta methodology. This publication describes the Tripod Beta incident investigation and analysis methodology, giving step-by-step instruction and detailed guidance for both new and experienced users in the application of Tripod Beta. It is recommended reading for anyone looking to apply a consistent and robust incident and accident investigation and analysis methodology, particularly incident investigators, as well as those who have undergone training in Tripod Beta.

Incident Investigation Software. Do-check-act) within 1 software framework. Tripod - Beta. Version of the BowTieXP software. Navigator Brochure (Download. Look at most relevant Tripod beta free download websites out of 15 at KeyOptimize.com. Tripod beta free download found at i3pod.com, sourceforge.net, freedownloadb. Tripod Beta Download software free downloads. Tripod Beta Download shareware, freeware, demos: Mail Notifier Beta by DanielNET Software, Evasion7 download.

Download the for a free sample of the full manual. ISBN: 9 7808 5293 8539 Version: 5.1 (2017) Price: £150.00 Click to purchase this title. Changes from v5.01 (2015) For users of version 5.0 and 5.01, a small number of changes have been made to the most recent version of Tripod Beta(version 5.1), predominantly to cross-reference the 2016 EI guidance as well as other resources. A list of the most significant changes are as follows:.

Cross-references made to EI Learning from incidents, accidents and events throughout. Removal of the term ‘sub-standard acts’ throughout. This term suggests a judgement of the individual’s actions, and gives the mistaken impression that Tripod Beta is about blaming individuals, whereas in fact this is antithetical to Tripod.

‘Action’ or ‘omission’ are the preferred terms. Reference made to Chartered Institute of Ergonomics and Human Factors whitepaper, which provides an interesting, and potentially useful, definition of a ‘barrier’.

Inclusion of an additional annex drawing attention to the free STF resource Changes from v5.0 (2014) For users of version 5.0, a number of minor clarifications were made to v5.01:. Figure 2 preconditions box now reads 'Error/violation promoting conditions/perceptions/beliefs'. Figure 3 has been simplified to only show failed barriers. Section 3.3.1 table 10: clarified that inadequate barriers should be explained using a full causation path, whereas missing barriers can be explained with either a full causation path or underlying cause only. Likewise, it is now made explicit on page 63 that the full causation path is permitted for missing barriers. Clarified on page 30 and page 91 that trios without a barrier do not need to be collapsed if it is clearer to include them in the diagram. 'Reckless' violations added as a category to the human failure taxonomy in figure E.1, and 'Reckless' and 'Unintentional' violations added to figure 15 for consistency.

Chess board now used in figure E.2 to illustrate conscious behaviour. What is Tripod Beta? (.zip 2.14mb) (.zip 7.6mb) Each company has its own organisational culture, within which reside a number of processes or systems, e.g. The HSE management system, and quality management system. One element in these systems will be a process for incident investigation, analysis and reporting, the purpose of which is to identify why things went wrong so that they can be corrected and future losses and business interruptions prevented.

The steps in this process start with initial fact finding followed by detailed investigation, testing and analysing facts and assumptions, and formulating corrective actions to improve the management system and organisational culture that allowed the incident to occur. Developed in the early 1990s, Tripod Beta is an incident investigation and analysis methodology designed in line with the human behaviour model. It was explicitly created to help accident investigators model incidents in a way that allows them to understand the influencing environment and uncover the route organisational deficiencies that allowed that incident to happen. Using Tripod Beta, incident investigators model incidents in terms of: objects (something acted upon, such as a flammable substance or a piece of equipment), agents (something that acts upon objects, such as a person or a fire) and events (the result of an agent acting upon an object, such as an explosion). Working back from the 'main event' (the incident), this allows us to understand fully what happened and how an incident happened. To understand why the incident happened, the next step is to determine what barriers where in place to prevent those objects and agents acting in the way they did and why they failed.

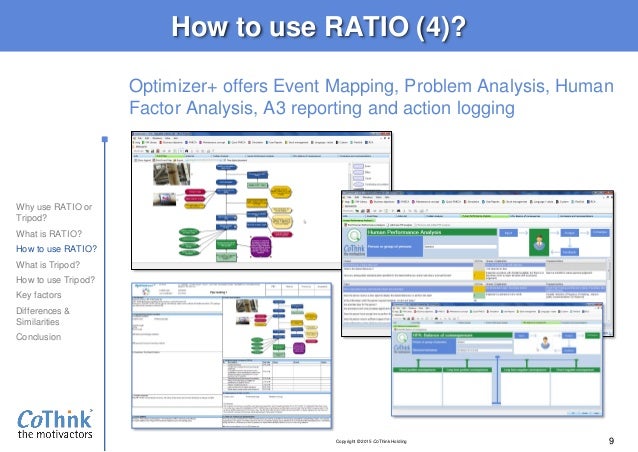

Tripod Beta teaches us to look at the immediate causes of either the act that led to the incident, the psychological precursors to that, and ultimately underlying organisational deficiencies. In the Tripod Beta methodology the investigation process goes hand-in-hand with the analysis process. From the preliminary investigation report, possible Tripod Beta models of the incident are produced which leads to further investigation and fact finding which in turn leads to a validation and refinement of the model. This continues until all relevant facts have been identified and the ‘Tripod Beta tree’ accurately reflects the incident. The result is a saving in time and effort, a deeper and more comprehensive analysis and a clearer understanding of the failures that must be addressed in order to make significant and lasting improvements in incident prevention. The methodology can be supported by software that provides the means to collect and assemble the facts from the investigation and to manipulate them on screen into a graphical representation of the incident and its causes.

What is IncidentXP? To dowload, email or print the product brocure. IncidentXP is our incident analysis software product which uses the same software framework as BowTieXP. This makes it possible to link incident analysis information to risk assessment information. However, IncidentXP can also be used as full-fledged stand-alone incident analysis tool.

The software is designed to learn from all incidents that have occurred in your company. The type of incidents may range from process deviations, to near misses, to small incidents, to major accidents. And the incidents can relate to both Process Safety and Personal Safety. Why IncidentXP? Learning from incidents is a challenge for most organizations.

One of the biggest reasons for this is that the analysis performed on the incident does not provide an adequate basis for high quality recommendations which will change the organization for the better while still being realistic. IncidentXP will assist you in making recommendation focused on a specific barrier or on the organizational level (basic risk factor level). Only using incident analysis is not enough. Bowtie risk assessment can be used to check if the investigation covered everything that was supposed to be done before we finalize an incident analysis.

Additional, the incident analysis results should link back to the risk assessment to aggregate and detect trends across incidents. By providing both risk assessment (BowTieXP) and risk monitoring (IncidentXP) we close the circle of Deming (plan-do-check-act) within 1 software framework. Tripod - Beta The tripod method is a way of conducting incident analysis. It is mostly used for high risk, complex incidents, since it is a very extensive and detailed method. Training is highly recommended when using the tripod method. A Tripod Beta tree is built in three steps. The first step is to ask the question: ‘what happened?’.

All the events that happened in the incident are listed as a chain of events. The next step is to identify the barriers that failed to stop this chain of events.

The question that is asked in this step is: ‘How did it happen?’. When all the events and the failed barriers in between are identified, the reason for failure of these barriers is analyzed. The last question for this step is: ‘Why did it happen?’. For each of the failed barriers a causation path is identified.

Tripod Beta Method The tripod method is a way of conducting incident analysis. It is mostly used for high risk, complex incidents, since it is a very extensive and detailed method. Training is highly recommended when using the tripod method. A Tripod Beta tree is built in three steps. The first step is to ask the question: ‘what happened?’.

All the events that happened in the incident are listed as a chain of events. The next step is to identify the barriers that failed to stop this chain of events. The question that is asked in this step is: ‘How did it happen?’. When all the events and the failed barriers in between are identified, the reason for failure of these barriers is analyzed. The last question for this step is: ‘Why did it happen?’. For each of the failed barriers a causation path is identified. All the items that appear in the Tripod Beta method are explained in more detail below.

What happened? First it needs to be identified what happened during the incident; what events occurred. This is the core of the tripod diagram and is represented with three shapes, the head ‘trio’. These three elements are:.

Event. Hazard. Object The trio can be explained as an AND gate, both the Hazard and the Object need to be present for the Event to occur. The Hazard acts on the Object to change its state or condition that is described as the Event.

In a tripod tree there can be multiple trios. Hazards and Objects can form new Events. Autosport 660i jump starter. Event In the tripod theory an Event is a happening, a ‘change of state’, whereby an object is affected by a Hazard.

All events may cause potential injury, damage or loss. Examples of events are:. Cut in a finger. Car collision. A failed money investment Hazard A Hazard is an entity with the potential to change, harm or damage an object upon which it is acting.

Hazards can be a physical energy source or can have a more abstract nature. Examples of a Hazard are:.

Working on height. Explosive material. Economic crisis Object The Object is the item that is changed by the Hazard. The Object can be someone or something that is harmed, changed or damaged. Examples of Objects are:. Employee.

IT system. Environment 2. How did it happen? Barriers The second step in the tripod analysis is to analyze how the incident could have happened by identifying the failed barriers. The barriers can be placed between the Hazard and the Event and between the Object and the Event. To identify these two types of barriers two questions are asked: What Barriers should have prevented the exposure to the Hazard?

Free Beta Software Downloads

What Barriers should have protected the Object from the Hazard? A Barrier is something that should prevented the meeting of an Object and a Hazard. It protects people, assets, environment from the negative consequences of a Hazard.

Barriers can have their effect on the Hazard (e.g. Insulation) or the Object (e.g. In a Tripod analysis a Barrier can be qualified as failed, missing or effective.

Why did it happen? The last step is to identify why the incident happened; what caused the Barriers to fail. To analyze this we follow a certain pathway, called the ‘Causation Path’. The causation path consists of three items:. Immediate Cause. Precondition.

Underlying Cause Immediate Cause The Immediate Cause explains the human act that directly caused the Barrier to break. The Tripod method is based on the Human Error theory. This theory states that incidents happen when people make errors and fail to keep the barriers functional or in place. These errors are Immediate Causes.

Examples of Immediate causes are:. Neglecting to wear PPE. Wrong design decision. Inappropriate use of tools Precondition The Precondition is the environmental, situational or psychological ‘state’ in which the Active Failure takes place. It explains the context of the human error and it provides the control breaching capacity of the Active Failure.

This can be related to supervision, training, instructions, procedures, etc. Examples of Preconditions are:. Bad sight. Budget squeeze. Poor ergonomics of tools Underlying Cause Underlying Causes are the organizational or systemic deficiencies that create Preconditions. The Underlying Cause acts on a system level, it always involves the organization. A Underlying Cause is not incidental, but is present for a longer time; it is an underlying failure.

Examples of Underlying Causes are:. Inadequate training. Failure to identify hazards. Imbalanced budgets.